DPF Cleaning Specialists

Serving fleets or owner-operators in Maryland, Virginia, Washington, D.C., and Pennsylvania

Why Choose Us?

Emissions Cleaning Services, Inc., provides safe, prompt and reliable DPF cleaning.

We can clean all makes and models of diesel particulate filters in an environmental, EPA-compliant manner. Our process professionally removes virtually all PM-10 soot & ash from the channels of the filter, restoring the DPF to OEM-serviceable conditions.

We’re regional—we live and work where you do: right here.

Emission Cleaning Services, Inc. is a locally owned and operated, full-service, DPF cleaning service provider located inside the Butler Automotive Service location in Rockville MD. We consistently offer large business solutions with small business responsiveness. Your business is our top priority.

We are proud to serve clients throughout Maryland, Northern Virginia, Washington, D.C. and beyond!

DPF Cleaning Done Right!

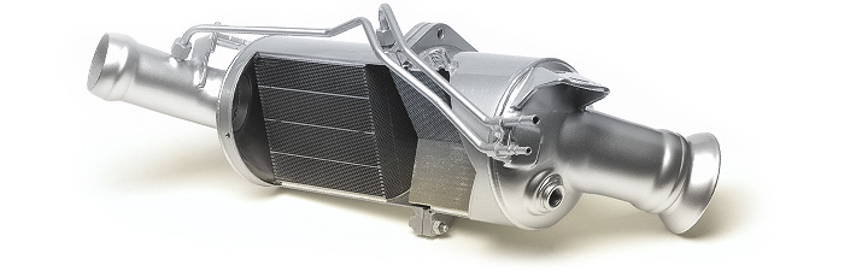

At ECS we understand the importance of providing prompt and superior services. Downtime is critical to any business. Our state-of-the-art cleaning processes surpass conventional in-house DPF cleaning, offering the latest technology with full multi-point inspection of your filter with before-and-after flow testing without cutting, modifying or welding the filter units.

We offer all commercially acceptable filter cleaning processes: Pneumatic, Thermal and Aqueous.

ECS can service DPFs, EGRs, SCRs, DOCs, catalytic converters, inter-coolers, manifolds and other components. We provide the latest cleaning technology that provides the best performance at an economical price with a fast turnaround.

- Local pickup/deliveries

- 24-hour express turnaround time available

- Stage 3 cleans on ALL filters using state-of-the-art equipment

- Competitive pricing

- We clean and service nearly all DPF and DOC in the market today

- Sensor bung repairs/replacements

- Gaskets/clamps in stock

- Fleets welcomed!

- Free air flow & back pressure testing

Diesel Particulate Filter is a Maintenance Item!

After a DPF has done its job by removing particulate matter, the soot is left behind and builds up over time to reduce the filter’s effectiveness. A diesel engine can last more than 30 years. That said, a DPF filter must be removed and cleaned multiple times. As more and more soot & ash becomes compacted in an uncleaned filter, it shortens the life of the filter which ultimately results in engine derate or costly repairs to the entire After Treatment System.

A DPF, before (top) and after (bottom) cleaning.

Preventative Maintenance

As the old adage goes…it is easier to prevent something bad than to deal with the results.

DPF CLEANING SERVICES

Remove the soot and ash buildup from all types of DPFs including; cars, SUVs, trucks, buses, and plant equipment.

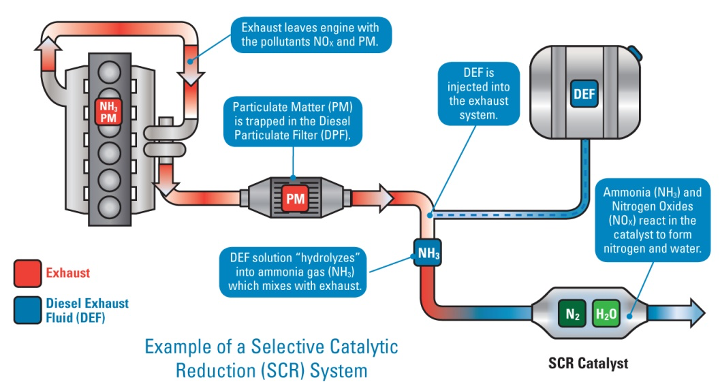

SCR CLEANING SERVICES

Remove the chemical byproducts from NOx conversions Capable of cleaning all European & Japanese late model vehicles Including Volvo and Scania.

EGR CLEANING SERVICES

Removes thick, black oily sludge and soot from EGRs & inlet manifolds.

DPF CLEANING SERVICES

Remove the soot and ash buildup from all types of DPFs including; cars, SUVs, trucks, buses, and plant equipment.

Benefits of a clean DPF:

- Improved vehicle performance

- Increased fuel economy

- Less downtime

- Extended DPF life

- Experience fewer regenerations

- Lower maintenance costs

Preventative maintenance of a diesel particulate filter (DPF) is essential to reliable engine operation.

Do not overlook important After Treatment Systems maintenance. Many owners often do and end up paying more in poor mileage, under-performing, down time and breakdowns. At Emissions Cleaning Solutions, Inc., we employ state-of-the-art hydraulic, thermal and pneumatic cleaning machines to clean particulate filters. All filters are tested before and after cleaning to certify air flow rates.

We provide pickup and delivery normally with 24-hour turnaround. Same day services are available by appointment.

ECS’s advanced particulate cleaning process for DOC, SCR, EGR, and catalytic converters. We provide cleaning services for all passive and active regenerative DPFs and all OEM-equipped, on-road, off-road and stationary DECS (Diesel Emission Control Strategies). Our DPF cleaning is a fast and reliable industry accepted method for cleaning Emission Control Filters.

You may need a DPF Cleaning for your DPF/ DOC/SCR if:

- Reaches manufacturer recommended service interval

- ERG Failures

- Constant Engine Fault Codes

- Back pressure increases

- Frequent and prolonged regeneration

- Diminished performance or fuel economy

- Check engine light

Our cleaning process uses the best in class, proven technology, yielding the very best results.

Cleaning your emission systems will extend the life of your filter, reduce breakdowns, maintain engine power, promote fuel economy and safeguard the environment. It will also protect upstream components such as turbo, EGR cooler, EGV valve and intake runners.

Cleaning DPFs and other similar filters in an uncontrolled environment is extremely dangerous to one’s health and often damages the units voiding the warranty.

The waste can be extremely hazardous and should be treated as such.

Unconventional cleaning methods lacking proper documented flow testing can VOID vehicle warranties for After Treatment System components.

A dirty DPF can create upstream failures in the after treatment system, ERG, turbo and engine. Regens are important but over time will not do the job. Accumulated particulate matter and noncombustible materials can remain trapped in the filter. To properly clean the DPF it must be removed from your vehicle and put through our special cleaning process. The benefits of a clean DPF include:

- Less downtime

- Improved vehicle performance

- Increased fuel economy

- Extended DPF life

- Fewer regenerations

What is a Diesel Particulate Filter?

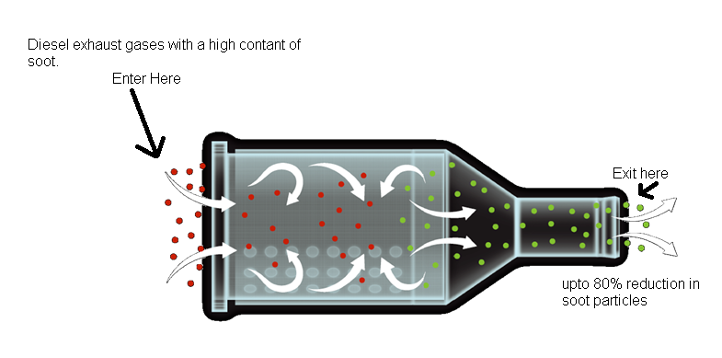

A DPF is a device installed in the exhaust stream of diesel engines made after Jan. 1, 2007 in response to more stringent emission regulations. It is designed to remove diesel particulate matter or soot from the exhaust gas of a diesel engine.

About DPF’s:

The diesel particulate filter (DPF) is designed to remove the particulate matter (soot) from the exhaust. In vehicles with a DPF, exhaust flows through an open inlet channel and is restricted at the plugged end, where it is forced through porous walls that trap soot. The exhaust then passes through the wall and out of the adjacent cell where the outlet end is open.

Adverse health effects have been linked to harmful particulate matter found in diesel emissions. The carcinogenic components can cause asthma, respiratory distress and cardiovascular issues. The most harmful of these particles are less than 10 microns in size, and are able to get into the deepest regions of the human respiratory system.

Diesel engines produce a variety of particles during combustion of the fuel/air mix due to incomplete combustion. The composition of the particles varies widely depending upon engine type, age, and the emissions specification that the engine was designed to meet.

Diesel particulate matter resulting from the incomplete combustion of diesel fuel produces soot (black carbon) particles. These particles include tiny nanoparticles—smaller than a thousandth of a millimeter (one micron). Soot and other particles from diesel engines worsen the particulate matter pollution in the air and are harmful to health.

New particulate filters can capture from 30% to greater than 95% of the harmful soot. With an optimal diesel particulate filter (DPF), soot emissions may be decreased to 0.001 g / km or less.The quality of the fuel also influences the formation of these particles. For example, a high sulfur content diesel produces more particles. Lower sulfur fuel produces fewer particles, and allows use of particulate filters. The injection pressure of diesel also influences the formation of fine particles.

A DPF, before (top) and after (bottom) cleaning.

Regeneration:

Regeneration is the process of removing the accumulated soot from the filter. This is done either passively (from the engine’s exhaust heat in normal operation or by adding a catalyst to the filter) or actively introducing very high heat into the exhaust system. On-board active filter management can use a variety of strategies:

- Engine management to increase exhaust temperature through late fuel injection or injection during the exhaust stroke

- Use of a fuel borne catalyst to reduce soot burn-out temperature

- A fuel burner after the turbo to increase the exhaust temperature

- A catalytic oxidizer to increase the exhaust temperature, with after injection (HC-Doser)

- Resistive heating coils to increase the exhaust temperature

- Microwave energy to increase the particulate temperature

All on-board active systems use extra fuel, whether through burning to heat the DPF, or providing extra power to the DPF’s electrical system, although the use of a fuel borne catalyst reduces the energy required very significantly.

Typically a computer monitors one or more sensors that measure back pressure and/or temperature, and based on pre-programmed set points the computer makes decisions on when to activate the regeneration cycle. The additional fuel can be supplied by a metering pump. Running the cycle too often while keeping the back pressure in the exhaust system low will result in high fuel consumption. Not running the regeneration cycle soon enough increases the risk of engine damage and/or uncontrolled regeneration (thermal runaway) and possible DPF failure.

Diesel particulate matter burns when temperatures above 600 degrees Celsius are attained. This temperature can be reduced to somewhere in the range of 350 to 450 degrees Celsius by use of a fuel borne catalyst. The actual temperature of soot burn-out will depend on the chemistry employed. The start of combustion causes a further increase in temperature. In some cases, in the absence of a fuel borne catalyst, the combustion of the particulate matter can raise temperatures above the structural integrity threshold of the filter material, which can cause catastrophic failure of the substrate. Various strategies have been developed to limit this possibility. Note that unlike a spark-ignited engine, which typically has less than 0.5% oxygen in the exhaust gas stream before the emission control device(s), diesel engines have a very high ratio of oxygen available. While the amount of available oxygen makes fast regeneration of a filter possible, it also contributes to runaway regeneration problems.

A DPF, before (top) and after (bottom) cleaning.

Diesel Particulate Filters (DPF) are emissions devices installed on all over the road diesel engines manufactured since 2007.

DPF’s are designed to burn soot. Unburnable ash gradually collects in your filter causing excessive back pressure and regenerations. New DPF’s cost $2,500 – $5,000. We can service your DPF at a fraction of the cost of a new filter.

Failure to service your DPF can cause the following problems:

- Down Time

- Poor Fuel Economy

- Engine Related Failure

- Lost Revenue

- Frequent Regenerations

- Excessive Engine Back Pressure

Cleaning:

Even with passive and active DPF regeneration, you will need to remove the DPF from the vehicle for a more thorough cleaning. You might notice that the truck needs more passive and active regenerations to continue running properly. You might also notice decreased performance or a lower fuel economy. These are indications you need to have a DPF becoming clogged.

A regular cleaning will help ensure the vehicle operates as designed and help you avoid a costly DPF replacement. Incorporating an after treatment system inspection into your fleet’s preventive maintenance routine can help identify dirty filters before they lead to unnecessary downtime.

The thorough cleaning is completed with specialized equipment. This is completed by heating the filter to loosen the particulate and then using either forced air or fluid to remove the soot from within the filter. There are advantages and disadvantages to the air or fluid method. We offer both cleaning processes.

DPF Cleaning

Even with passive and active DPF regeneration, you will need to remove the DPF from the vehicle for a more thorough cleaning. You might notice that the truck needs more passive and active regenerations to continue running properly. You might also notice decreased performance or a lower fuel economy. These are indications you need to have a DPF becoming clogged. A regular cleaning will help ensure the vehicle operates as designed and help you avoid a costly DPF replacement. Incorporating an after treatment system inspection into your fleet’s preventive maintenance routine can help identify dirty filters before they lead to unnecessary downtime.

Pre-Cleaning Inspection & Data Recording

All products coming in for service are tagged with customer information from pickup or drop-off, to ensure your filter is tracked and returned to you. All products are evaluated and tested. We check all bungs for cracks or damaged threads.

We start the DPF/DOC cleaning worksheet to record all repairs and cleaning services. We inspect 20 cells for damage, chips, gouges, surface cracks, melting, oil/fluid contamination, etc. If no faults are detected the cleaning service continues to the next step.

Before & after cleaning with flow test & weight

This test measures and records weight and air flow on each filter. This is used to measure filter performance at each stage of the cleaning process and to identify defective filters.

The baseline data listing such as weight, back pressure and air flow readings are documented with cleaning targets ranges to record before and after cleaning air flows on customer filters to determine success or failure on cleaning the filter.

Before and after measurements ensure warranty compliance.

Pneumatic Cleaning Option

DPFs and DOCs are cleaned using a pneumatic system. This process uses computer controlled bilateral high-pressure air through the filter to ensure each cell is targeted and diagnosed individually. This will remove all cell particulate matter and micro-pore inhibitors to restore the filter to its optimum filtration capabilities. The filter will be cleaned until ash is completely removed. This process may take up to 45–60 minutes.

The TrapBlaster is the flagship of the FSX product line, utilizing patented technology to clean filters significantly better than competing designs. Using state of the art technology, these machines clean diesel particulate filters like no other. Using automatic or manual operation, the operator can immediately see the progress and status of the filter cleaning operation as it happens — no more “guessing” whether the filter is clean. If cells are particularly bad, switch to manual operation and spot-clean the affected areas. Upper and lower air jets allow cleaning from both ends of the filter, not just one. The FSX technology has a built-in diagnostic feature that makes it possible to detect filters that are failing.

Fully automatic operation with manual capabilities for custom cleaning of particularly bad filters. High pressure air jets clean from both ends to ensure optimum filter recovery. Cell by cell cleaning ensures the entire filter is cleaned. Adjustable nozzles allow access to hard to reach flanges and recessed cavities. “Side Stitch” mode allows focused cleaning on the outer edge of filters typically under cleaned by other systems. Diagnostic features during cleaning allow detection of failed cell walls and defective filters.

Thermal Cleaning Option

Thermal regeneration will burn off any remaining soot deeply set in the ceramic cell walls. The thermal process uses ambient air while heating. Carefully programmed to deliver just the right amount of heat. No air being pumped through the filter reduces the risk of cracking the filter or causing thermal stress. 100% of soot is burned off during the thermal regeneration. This oxidizes any soot and loosens leftover ash deposits. After this cleaning, the DPF has a final airflow test.The DPF is placed in a specialized kiln, with temperatures of 1112°F.

| Thermal Cleaning | |

| DPF State | Bake Time |

| Dry | 12 hours |

| Oil/Fluid Soaked | 24 hours |

| Severely Oil/Fluid Soaked | 48 hours |

Aqueous Cleaning Option

Water based DPF Cleaning is suitable for all diesel particulate filter types from cars, light, medium and heavy trucks, buses, stationary power plants and off road equipment equipped with a diesel particulate filter. It efficiently removes virtually all PM-10 (soot & sulphated ash) from the channels of the filter, restoring the DPF to OEM conditions.

Most DPF cleaning Systems are designed to clean modular canister style filters found on heavy trucks that when the DPF is removed, the full inlet and outlet surfaces of the filter are easily accessible. Many diesel particulate filter designs such as those on cars, light and medium sized trucks have the DOC and DPF housed in a sealed housing with small diameter exhaust tubing preventing access to the inlet or outlet surfaces of the filter making it difficult or impossible to clean. In these instances the DPF must be cut open, cleaned and welded back together again to restore the filter to serviceable standards or simply replace the DPF costing thousands of dollars.

Emission Cleaning Services can clean any make and configuration of diesel particulate filter without cutting, modifying or welding by simply connecting the appropriate fitting.

Patented H2O Solution Flush Cleaning Option

Our DPF cleaning service uses state-of-the-art technology that is fast and cost effective. This process achieves 98% of the original condition of the filter with certified results.

H2O Solution Flush Cleaning…

- cleans all types of particulate filters for cars, buses, trucks, and heavy equipment & catalysts of big trucks (SCR)

- performs the entire cleaning cycle (washing and drying) in one machine

- cleans one DPF in 30 minutes

- ensures the recovery of the original efficiency of the DPF

- gives verifiable results providing the backpressure test before and after cleaning process: this allows an instant diagnosis of the filter and gives you a check on the quality of the cleaning once the filter is done

- has an integrated printer, so the filter can be delivered to customers with a report that ensures a successful cleaning

- reduces the environmental impact: it works in a closed system, which does not release dust emission into the environment

Main Benefits

- Total removal of PM (Particle Material) 10 residuals

- Removals of all residuals

- Removal of cerium residuals

- Efficient cleaning of all types of particulate filter and catalyst

- Safety of the filter

- Preservation of the noble metals of the DPF and catalyst

- Easy, fast, and cost effective

- Environmentally friendly

- Cleans all types of filters, both off cars DPF/DOC/FAP, buses and trucks, and catalysts off big trucks (SCR) as well.

- Easy and Fast

- Verifiable Results

- Backpressure & Air Flow testing before and after each cleaning cycle with a computer printed receipt documenting testing results including weigh, flow test and Pin gauge all DPFs

- DPF and DOC cleaning practices that restore filters to perform in a OEM “like new” condition

- Rapid 24 hour turn around on most filters. Hard to clean oil and coolant-soaked filters are always welcome

- Super convenient Local Pick Up & Delivery

After this cleaning process, the DPF has another airflow test.

Diesel Particulate Filters Recommended Cleaning Schedules

Since January 1, 2007, diesel particulate filters (DPFs) are a federal requirement to reduce pollution from all new trucks.

They are installed in the exhaust stream, and consist of two chambers…

- The first traps the NO gas and converts part of it to NO2, which is much less harmful to the environment.

- The second chamber burns the soot that’s caught, leaving a small amount of ash in the filter. Over time, the ash builds up and reduces the filter’s effectiveness.

How They Affect You

While very helpful to the environment, DPFs cost thousands of dollars and are often the root cause for problematic vehicle regeneration, ERG failures & After Treatment System dash lights and fault codes.

Without proper care and regular cleaning, the DPF will have a shorter lifespan and a damaged core resulting in unscheduled downtime. New DPFs can cost as high as $5,000.

What is the Recommended Interval for Diesel Particulate Filter Cleaning?

The interval for Diesel Particulate Filter cleaning varies between manufacturers specification, engine condition, duty cycle, and type of lube oil used in the engine. Most DPF manufacturers recommend cleaning the Diesel Particulate Filter once per year or about every 1000 hours of engine operation. In some cases, the required cleaning interval may be much shorter.

With long haul OTR (Over the Road) vehicles it is recommended removing the DPF for cleaning at 120,000 – 250,000 highway miles. These vehicles with considerable highway time normally have sufficient time for passive regeneration during use.

For local vehicles & equipment with short travel distances, High PTO hours, high idle times and moderate daily starting and stopping the recommended cleaning interval is every 75,000 miles or 1,000 hours. This is due to the vehicles not having adequate time for passive DPF regeneration to occur during use.

Testing has found that ash begins hardening in the filter cells as early as 50,000 miles. Once ash hardens it can cause permanent damage and cracking.

DPF filters serviced by ECS are returned with a full report on the before and after condition of your DPF.

We offer all commercially acceptable filter cleaning processes; Pneumatic, Thermal and Aqueous.

Soot & Ash Disposal

Compliant SOOT & ASH Disposal with every service. We keep your company GREEN!

In 2009 the EPA issued a technical bulletin on Diesel Particulate Ash Disposal. This bulletin offers guidance on how generator status is defined. Here is a link to the complete technical bulletin on DPF Ash Disposal. Many companies quickly fall under “generator” classification status unknowingly.

The EPA’s Standards Applicable To Generators Of Hazardous Waste is an online resource outlining for companies what to know regarding hazardous waste. Their policy clearly states that all organizations are responsible for the ultimate destination of their hazardous waste. The burden of proof rests upon the waste generator.

The EPA website states:

“All generators must determine if their waste is hazardous and must oversee the ultimate fate of the waste. Furthermore, generators must ensure and fully document that the hazardous waste that they produce is properly identified, managed, and treated prior to recycling or disposal.”

The EPA sets the national standard on environmental concerns and several other agencies also have rules governing the disposal of hazardous waste. State based agencies must comply with all federal standards, however, additional state regulations exist. It is important to check the state level equivalent of federal agencies. The EPA website offers this convenient state-by-state guide.

Certificates of Disposal is an important document that provides waste generators peace of mind knowing that a reliable environmental services company assumes responsibility for processing the waste at a certified facility.

Each Certificate of Disposal contains by weight volume of materials and statement certifying all materials have been disposed of in accordance with federal and state regulations, DOT regulations and all applicable state and federal Environmental Protection Agency (EPA).

This provides proof of responsible soot & ash disposal and allows for businesses to record and track their company’s Soot & Ash generation and disposal by certified weight.

Farm Equipment and Tractor DPF Cleaning

- CASE DPF Cleaning Services

- New Holland DPF Cleaning Services

- Ford DPF Cleaning Services

- John Deere DPF Cleaning Services

- Mahindra DPF Cleaning Services

- Kubota DPF Cleaning Services

A tractor DPF collects exhaust soot and ash. Overtime as ash and soot builds up within Diesel Particulate Filter and will limit exhaust flow and increase back pressure. In turn this will reduce fuel efficiency on the tractor and often results in damage to other engine components such as ERG Valves and turbos. At about 2,000 hours of engine time the DPF will reach a point of ash accumulation. The tractor then requires a DPF cleaning.

A tractor equipped with a DPF offers full power without the pollution. You’ll experience fuel efficiency, decreased noise, and an increase in power. These engines exceed government standards when it comes to reducing PM, NOx, HC, and CO.

All DPF cleaning methods follow strict guidelines to ensure each DPF is restored to OEM flow specifications. Every DPF is cleaned following a detailed multi-step inspection, reporting, cleaning and testing process using state-of-the-art equipment.

Federal law requires all diesel vehicles and heavy equipment to have a DPFs and EGRs to meet carbon emission reduction act. Normal regeneration will clean the filter to 95%, and this means the regeneration process becomes less effective over time. Emissions Cleaning Services can restore filters to original factory spec flow rates (over 98%) saving thousands compared to replacing a clogged filter.

Light & Medium Duty DPF Cleaning

Keep the diesel engines in your vans, trucks, buses and cars running well, and the environment clear of soot and ash.

Diesel engines in cars and trucks produce soot and ash. Late model diesel cars and trucks (since 2009) have a Diesel Particulate Filter (DPF) installed in the exhaust system to catch soot from being released into the atmosphere.

The end result is an 80% cut in diesel particle emissions. This system is not without problems and most issues can be remedied with proper care and cleaning of the Diesel Particulate Filter.

Regular maintenance and cleaning is needed for a DPF. Over time soot and ash builds up and requires the DPF to be removed from the vehicle for cleaning.

Heavy Equipment DPF Cleaning

Stay on task and on deadline. Keep your equipment up and running with proper DPF cleaning and maintenance.

Many equipment owners and fleet operators experience problems with DPFs that are the result of the lack of a maintenance program for the DPF. Without proper maintenance and service the only thing you can depend on is unscheduled downtime, increased replacement costs, and poor fuel efficiency. Without proper DPF cleaning, the DPF will become the root cause for a host of problems as the DPF becomes plugged with soot and hardened ash plugs.

- Komatsu DPF Cleaning Services

- JCB DPF Cleaning Services

- DOOSAN DPF Cleaning Services

- John Deere DPF Cleaning Services

- HITACHI DPF Cleaning Services

- LIEBHERR DPF Cleaning Services

- CATERPILLAR DPF Cleaning Services

- KOMATSU DPF Cleaning Services

- VOLVO DPF Cleaning Services

Sprinter Van DPF Cleaning

Keep your fleet going with sprinter van DPF cleaning and maintenance.

Filters are a staple of engine maintenance. Air filters, oil filters or fuel filters and yes DPF filters. A well maintained DPF filter can provide strong fuel efficiency, reduce downtown and ensure reliable operation. A Sprinter Van diesel particulate filter needs to be inspected and cleaned.

- Chevrolet Express DPF Cleaning

- Ford Transit Connect DPF Cleaning

- Ford Transit 350 DPF Cleaning

- Freightliner DPF Cleaning

- Kenworth DPF Cleaning

- Ford DPF Cleaning

- Cummins DPF Cleaning

- Dodge Ram DPF Cleaning

- Peterbuilt DPF Cleaning

- Detroit DPF Cleaning

- Volkswagen TDI DPF Cleaning

Backup Generators/Gensets DPF Cleaning

Don't lose power at a critical time. Keep your generators working with proper maintenance and routine DPF cleaning.

Lightly used genset do not produce the sustained high temperatures needed to properly regenerate DPF filters. This quickly impacts the after treatment and other emissions related components. DPF filters become clogged with limited/light use in the same manner as commercial vehicles with low speed, limited highway hours and high parked idle times.

All Tier 4 Final EPA diesel engine emergency power generators are equipped with a Diesel Oxidation Catalyst (DOC) and Diesel Particulate Filter (DPF) that reduce diesel particulate matter.

Regeneration is the process of cleaning the DOC & DPF with high exhaust temperature sustained over an extended period of use under load. When the unit is under load the regeneration process occurs passively from elevated exhaust temperatures.

If soot and ash accumulates in the DPF the engine will automatically de-rate which will cause issues with connected electrical loads.

Simply bringing the engine up to full operating temperate in test mode periodically will not produce the same full filter regeneration that occurs when under sustained prolonged load.

The Diesel Particulate Filters and Diesel Oxidation Catalyst should be sent for cleaning every 24 months on a regular interval to avoid downtime to emergency power generators.

Even with rigorous maintenance and scheduled testing of backup generators & auxiliary power units the EPA compliant engines can fail because they cannot regenerate the DPFs with light loads and often the DPF filters quickly become full and clogged.

- Generac Power Systems DPF Cleaning Services

- Winco DPF Cleaning Services

- Kohler DPF Cleaning Services

- Echo DPF Cleaning Services

- Magnum DPF Cleaning Services

- Honeywell DPF Cleaning Services

- Westinghouse DPF Cleaning Services

- Cummins Power Systems DPF Cleaning Services

Garages, Auto Shops, Equipment Repair Services and Fleet Management

- Convenient Drop off, Pickup and Delivery. Same-day service is available by appointment

- 98% of original values restored

- 24 Hour turnaround*

- 12 Months guarantee

- No charge if we can’t clean your customers' DPF.

- Computerized flow test report for your own records

- Expert customer service

When your shop has removed the DPF our team can pick up the filter from your shop/garage location for 24-hour turnaround cleaning service.*

We do offer same day expedited drop off services. Simply bring the DPF to our facility for cleaning and we can have it ready the same day. Please call ahead to ensure availability.

We understand your customers are important and we aim to provide prompt and reliable service to ensure your customers' filters are cleaned and returned to you to get them back on the road again.

*Turnaround times may increase for heavily contaminated filters or “Wet” filters to allow for extended cleaning efforts.